How to Find Blades for Black and Decker Model 9422 Band Saw

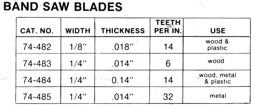

Blades Available that Fit a Black & Decker Model 9422 Band Saw:

- Catalog Number 74-482 Width: 1/8″ Thickness: .018″ Teeth/Inch: 14 Use: wood & plastic

- Catalog Number 74-483 Width: 1/4″ Thickness: .014″ Teeth/Inch: 6 Use: wood

- Catalog Number 74-484 Width: 1/4″ Thickness: .014″ Teeth/Inch: 14 Use: wood, metal & plastic

- Catalog Number 74-485 Width: 1/4″ Thickness: .014″ Teeth/Inch: 32 Use: metal

|

| Black+Decker Model 9422 Band Saw Blades |

I went ahead and researched to see what other blades would fit this band saw and found two more.

Alternative Blades for Black & Decker Model 9422 Band Saw:

- 52-3/4″ Long – 1/4″ Width; 24 Raker Tooth .014 Thick

- 52-3/4″ Long – 3/16″ Width; 8 Hook Tooth .014 Thick

Replacement Tires for Black and Decker Model 9422 Band Saw:

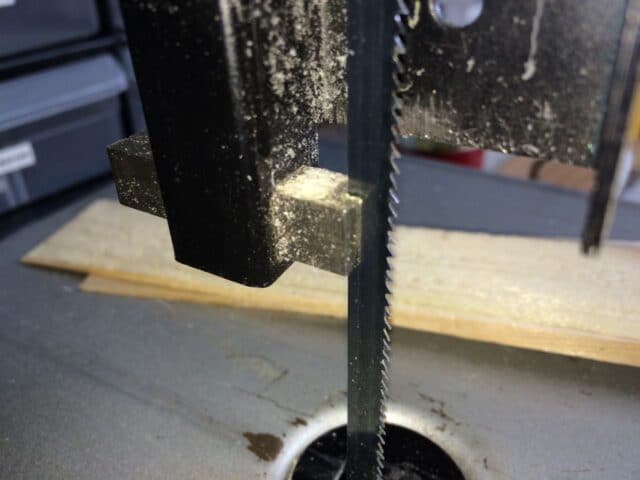

How the blades should fit in the bandsaw guide blocks:

The correct size blade will slip into the guide blocks. Here’s a picture of the blade correctly seated in the lower guide block:

|

| Black & Decker Model 9422 Lower Guide Block |

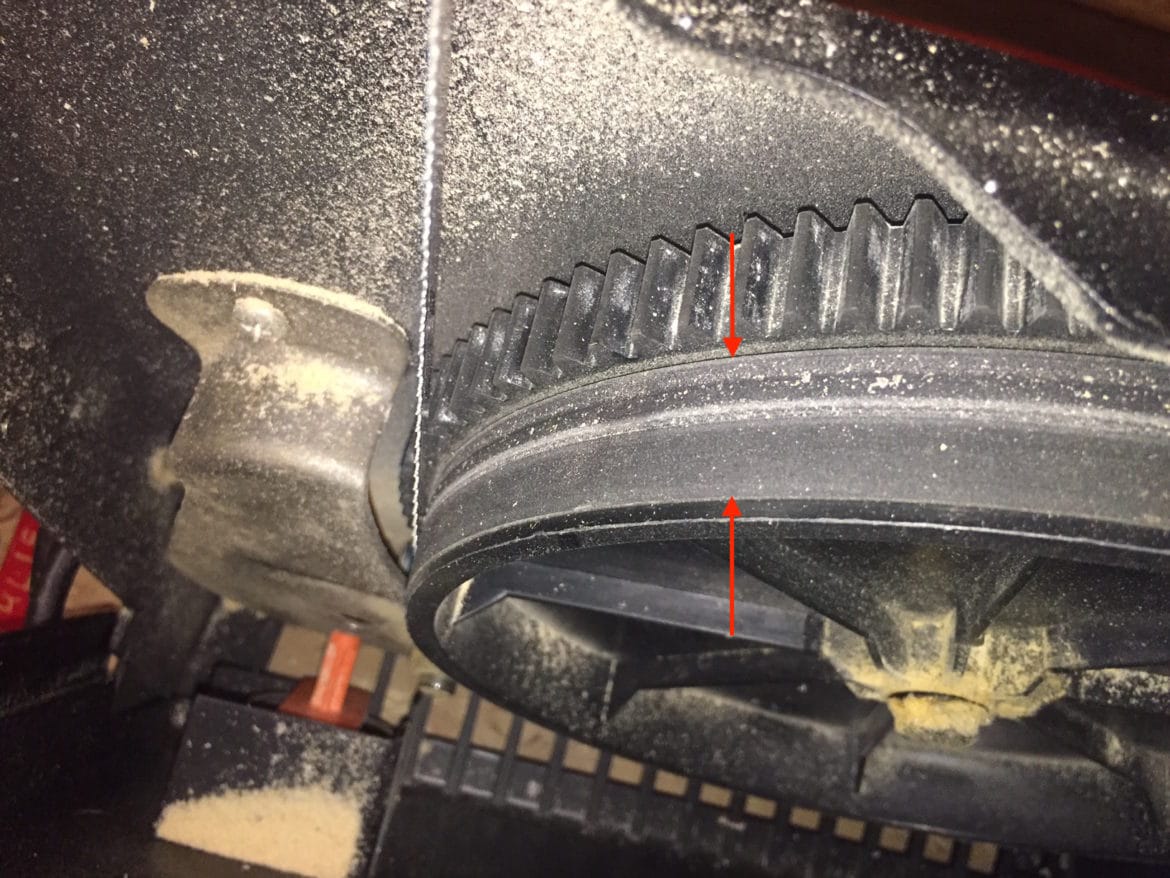

Here it is seated in the upper guide block:

|

| Black & Decker Model 9422 Upper Guide Block |

Useful Links:

- Official Black+Decker Model 9422 Band Saw Page

- Black+Decker Model 9422 Band Saw Manual (pdf)

- Black+Decker Model 9422 Band Saw Exploded View (pdf)

Amazon Associate Disclosure: As an Amazon Associate I earn from qualifying purchases. This means if you click on an affiliate link and purchase the item, I will receive an affiliate commission. The price of the item is the same whether it is an affiliate link or not. Regardless, I only recommend products or services I believe will add value to Share Your Repair readers. By using the affiliate links, you are helping support Share Your Repair, and I genuinely appreciate your support.

I accidentally purchased the 25 Thousandths thickness blades, but rather than returning it, I used a heavy duty cut off wheel on my Dremel tool and increased the size of the slot on the two blade guards and it works great.

I am missing the upper guide block on my 9422. If I recall correctly, you indicated that you were missing yours also. How did you solve this? Did you find one available for purchase, or did you somehow make a new one? Thanks!!!

I tried a thicker blade but it wouldn’t fit in the block–I have both blocks though. I attempted to search for them but can’t find them anywhere. I machine shop could make one for you easily. I think they are both identical so you could give them the other one as a guide.

Thank you for your feedback, John. And thank you for all the other info. regarding this band saw. Without your kind help, I’d still be searching for tires and blades. As for the block, I believe taking it to a machine shop might be too expensive for this saw, but perhaps I’m wrong. If anyone ever decides to make them or have them made, I’d be in for some. In the interim, I’m contemplating buying bar stock and cutting a slot into it for the blade. I’m currently trying to decide whether to use steel or brass for the block. I’m thinking that brass will be softer than steel and thus less likely to damage the blade if I don’t get the cut perfect. Any thoughts on the steel vs. brass decision?

This is a follow up to my previous post regarding guide blocks. I decided to make my own, and after thinking about it, thought that wood might work. When I googled this idea, I found that several people have used wood for band saw guides, and one person who appeared to be knowledgeable claimed that wood was superior to steel. It turns out that the upper and lower blocks are different in size, and the size I needed for the top guide was a rectangle, not a square. So I decided to buy a 3/8 hardwood dowel which would be just slightly too big in both dimensions. I cut off a 2 inch length and used a wood rasp, file, and sandpaper to square it off to fit the slightly smaller dimensions of the guide’s holder. I then used a hacksaw to cut the groove and since the other wood users recommended oiling it, I oiled it with WD40. I installed it and used it to make some practice cuts. So far, it seems like it will work superbly. Total cost was $5 for the five foot-long dowels which will provide the stock for a lifetime supply of guides. I offer this just in case it proves helpful to someone else. Take care!

Is there a tire for the 9422? My saw was given to me by my neighbor and until recently, I’ve been using it without any issues until recently when the blade began slipping off. I didn’t notice a tire (or remains of a tire) on either pulley and I’m not sure if there was one there in the first place. Can anyone advise on whether there should be one and if so, where can I get a replacement or rig the saw with something that will keep the blade from slipping.

Here’s a link for a set of tires: 2 Urethane Band Saw Tires for 7.5″ Black & Decker 9422 Band Saw

Where did you purchase your blades

Amazon.com, see the links above.

I just bought this bandsaw for $10 it’s not pretty but it seems to run, I plan on cleaning it up and slap on a new paint job but after seeing your post about the wheels I checked my saw out and it looks like the bottom drive wheel has the guide belt on it but the top wheel doesn’t have anything on it, I checked the amazon link out and it doesn’t look like I will be buying those for my saw lol is there any mods/hack I could do so I don’t have to spend that much on the saw, any info would be appreciated

looking for some blade guides

The Surface Feet Per Minute (SFPM) on the Black and Decker 9422 Band Saw is 660 SFPM according to the sticker on the motor. That speed is 2-6 times too fast for most metals and about 1/2 to 1/3 of the ideal speed for wood.

http://web.mit.edu/course/other/machineshop/Bandsaw/speeds.html

John, great service. Just one question. The parts manual for the 9422 seems to indicate only one tire being used and that it is on the drive pulley only (not the tensioner pulley). When I took mine apart to rehab it, only one (dry rotted) tire came out. Are you sure this unit is suppose to use two tires? I know all better quality band saws use two tires and I suspect it will run better with two. However, if it was designed for one, the tensioner adjustments may have to be modified to avoid over-tensioning the thin blade. Thoughts? Also, do you happen to know the SFPM on this saw?

Just a big “THANKS” for all of this information. I’ve had the band saw for many years, bought it new, and when the blade finally broke, there’s nowhere to find new blades. Your information is great! I’ll be able to get my saw running again and start on new projects.

That saw has helped me build everything from model pine-car racers to book shelves and book cases. Though it’s definitely for the smaller shop, it has pulled it’s weight in mine. So, thanks again. I appreciate all your input.

Thanks for sharing Richard, glad to have been of help.

I’m thinking about reviving this bandsaw which I bought for $15 at a yard sale I will have to invest another $50 in it would I be better off to just purchase a new one for a little over $100 or stick with this one?

Mitchell, thanks for the question. This is definitely a cheap bandsaw. It has plastic wheels and mine is very loud. I got it for about $100 originally (5 years ago) I think and I’ve not dropped any money into it since and don’t plan to. A bandsaw is a very handy tool that really is a must have in a workshop. If you can get a better one for not that much money I”d do that, if this is the only one you have, it is much better than nothing. You have to weigh the value and cost and hopefully this helps you to make that decision.

Thank you for posting this! Saved me hours when I found one these at a flea market recently but no blade.

my craftsman 71/2″ band saw knocks when cutting. but is silent when running. Any comments / advise

Bernie, thanks for the comment. I am guessing that you are hearing a knock once for every revolution of the band, when cutting, does that sound like what you are dealing with? If so, then what you’re running into is that the seam where the bandsaw blade overlaps and is welded together. The blade is thicker in that area and catches on the material you are cutting when that segment comes around and passes through the cut in the material. I found a great article on tuning a bandsaw, which includes rounding the back of the blade, which might solve your problem here (see step 11).

I’m reviving an old unused saw and your information was invaluable. Thank you very much.

Thanks for sharing Bruce. It’s not a great bandsaw as it is small, it is on the low end as far as bandsaws go, and it is very loud, but it is a bandsaw and they are very handy tools to have around when you need them!

Where to find the tires for it?

You can get them on amazon here: Urethane Band Saw Tires for 7.5″ Black & Decker 9422

I really appreciate the help I’ve looked everywhere

Glad you found what you needed Mike. Thanks for dropping a note.

I love the internet. Was looking for blades for this saw. I just bought it at a yardsale, but no blade. Did a search..and what do I find.. your page. Unbelievable. 🙂 Question: Did these saws come with a belts on the wheels? Mine doesn’t have them but I see them on ebay. More expensive than the saw though. Anyway, glad to find this webpage

Thanks

Yes, both wheels have belts on them. Please refer to these pictures I just took:

Appreciate the research and sharing. Contemplating picking one up I found listed today.

No problem. They aren’t a bad bandsaw but not heavy duty. They are amazingly loud I must say, so if you need to use it in an environment where it needs to be quite, I’d counsel against it. For a plastic wheel table-top bandsaw, it gets the job done though and I’ve even used it at work. Thanks for sharing Alain.

I just boaught one of those saws too & found, as you did, the blades are tough to find. Here’s another source: https://www.toolcenter.com/052_75_Band_saw_Blades.html

Thanks for the comment Jim. The blades you link to are more expensive but I guess if someone doesn’t like amazon.com then they could go with that site.

It looks like the blades at toolcenter are too thick for the 9422. They are .025 thick, while the 9422 calls for .014 thick blades